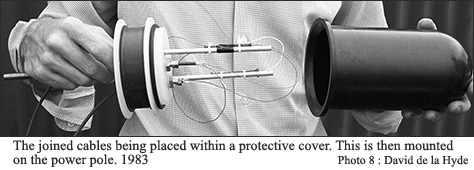

The hood also enclosed a ‘racetrack’ for neat storage of sufficient cable so that splicing may be easily performed at ground level.

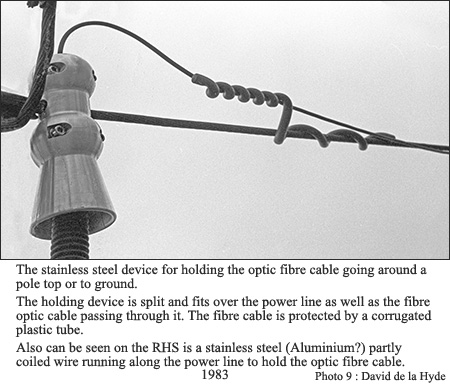

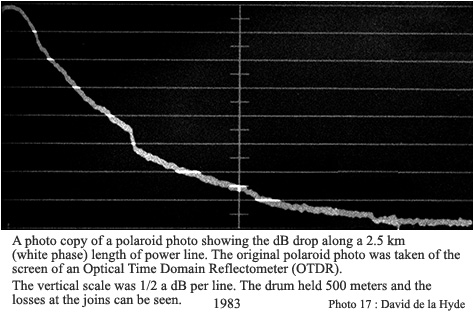

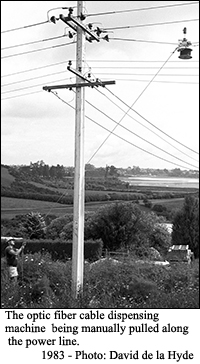

The fiber optic cable was alternated in 2.5km lengths between the three phases - on 33kV and 11kV sections. Possibly this was done to even out voltage stresses.

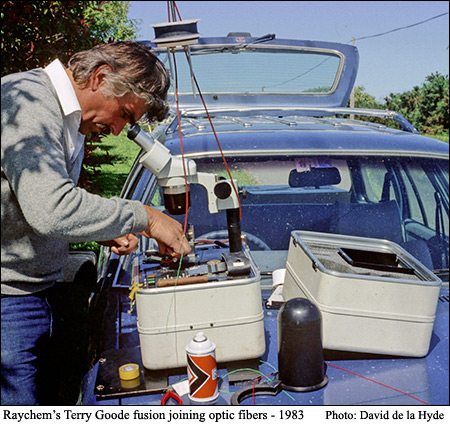

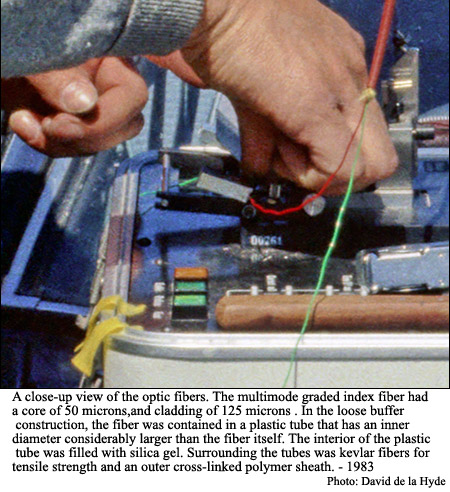

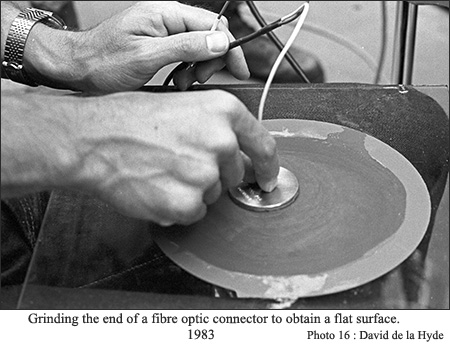

The fiber optic communication system had active components comprised of LEDs and photodiodes. The system operated in the 1.3 micron range of wavelengths. The fibers in the two core cable had an intrinsic loss of 0.5dB per kilometer. Losses at fusion junctions were at least 0 .2 dB.

The total losses on the 7.5 km cable were expected to be less than 20 dB and the signalling speed requirements for successful operation was less than 100 kbs.

The installation was replacing a possible voice frequency communications system that was used extensively by TEPB.

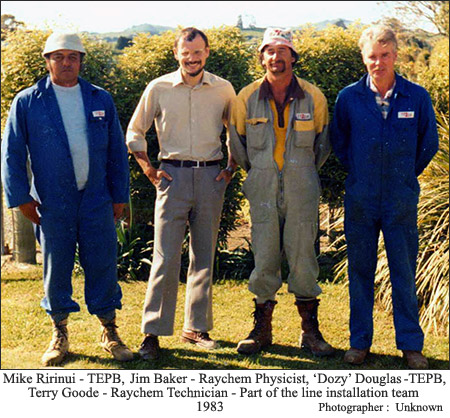

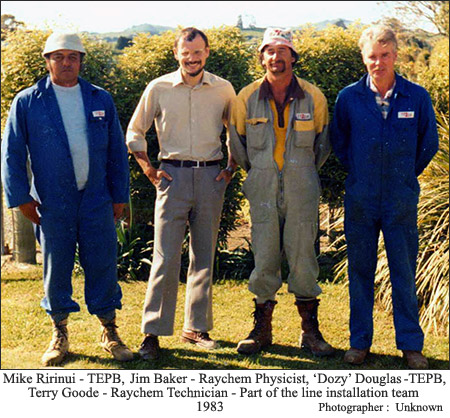

"In 1987 Raychem sold the wrapped cable technology, and Jim Baker, Terry Goode, me and half a dozen others who were developing Rayfos established a company called FOCAS to commercialise the product - a process that took a further 5 years.

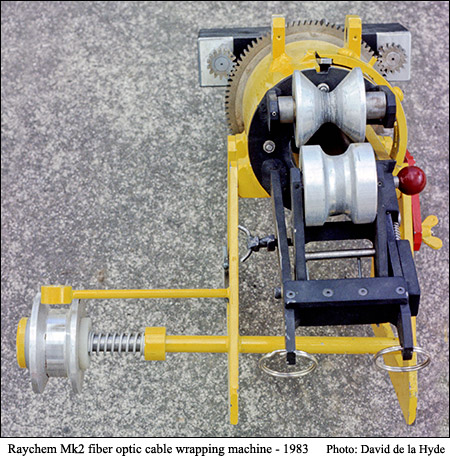

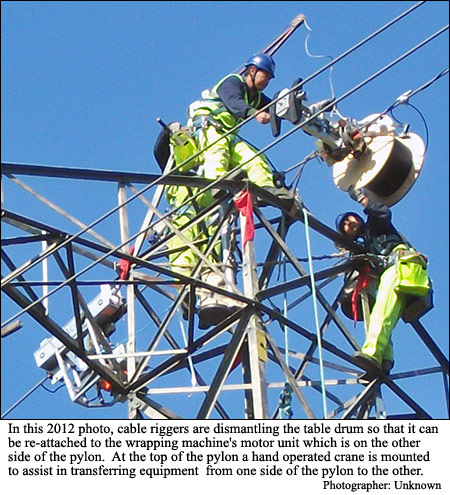

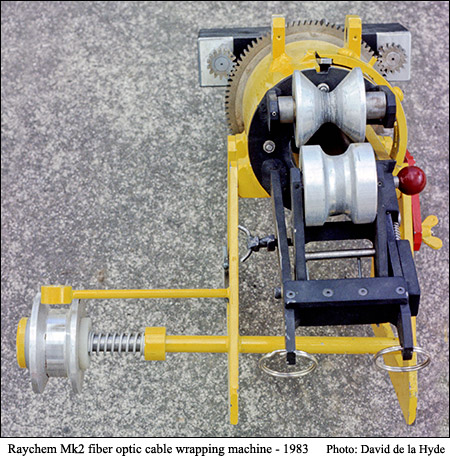

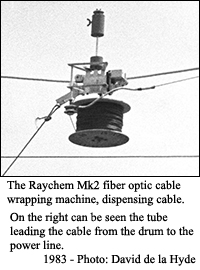

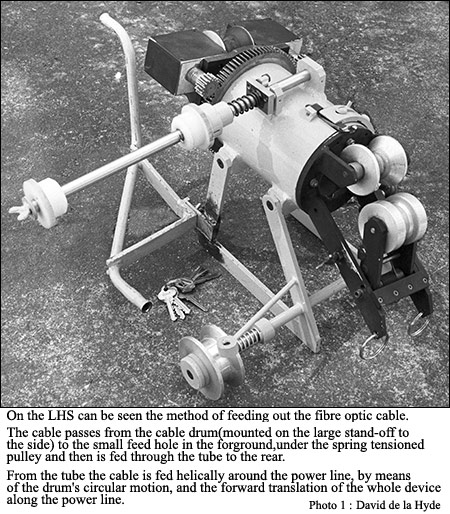

The product name was changed to SkyWrap on leaving Raychem. The wrapping machines grew in size and complexity as the years passed: The Mk3 was twice the size of a Mk2 to give longer distances between splices, the Mk4 had an automatically adjusting counterbalance and the Mk5 was double in size again.

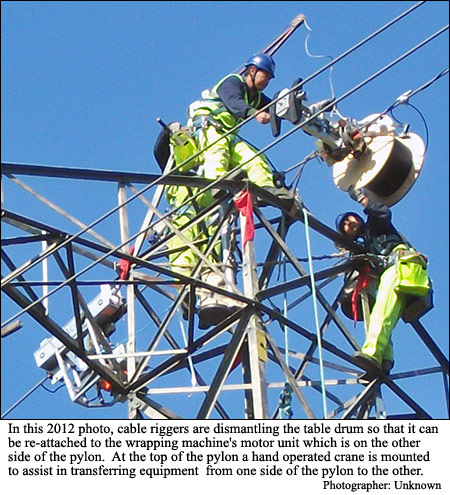

By about 1998, we reached the Mk6 wrapping machine which has sufficient counterbalance travel to allow wrapping on spans up to 1200m long and can carry up to 3km of cable per drum. The tension control mechanism gives a constant cable tension throughout the installation (unlike the early machines where the tension increased as the cable drum unwound).

This machine is also capable of installing 2 drums of cable at once to allow up to 144 fibres to be installed on one host conductor. In 2000, FOCAS was bought by AFL Telecommunications." - Jim Rowe, Product Manager, AFL. (2009)

FIRST AUSTRALASIAN OPTICAL ATTACHED CABLE (OPAC) POWER LINE INSTALLATION - 1983

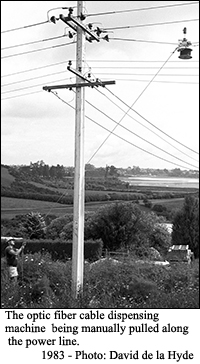

While on a visit to Tauranga, a sales representative for Raychem proposed a fibre optic cable installation on a power line to me for a communications link between zone substations.

I liked the idea - mainly because of the relative impunity to voltage/current surges due to lightning strikes. But the preliminary costing was more than twice that for an ordinary catenary multicore copper cable installation, and I would have difficulty justifying the purchase to the Chief Engineer (Eddie Graham) and in turn to the Board.

Thus I said that if an installation connecting a new switchyard/substation in Welcome Bay to NZED (New Zealand Electricity Department) switchyard/substation in Greerton for the same cost as our normal copper cable installation we would be interested.

Then I got a reasonably generous estimate made of the costs for a new 7.5 km cable installation on our part, and Raychem agreed to it. Effectively we paid for the installation and line costs and Raychem paid for the terminal equipment which was about the same cost. The proposal was approved by the Chief Engineer and the Board.

At the time the concept was a leap into the unknown, as I knew nothing about fiber optic communication links, but I thought that because of its apparent advantages, it was worth gaining experience with it. The WWW with its associated search engines was not available until the next decade.

The Greerton to Welcome Bay project was the third installation by Raychem: The first was in Kent in SE England in the middle of 1982 and the second was in Norway a couple of months before the installation in 1983 at Tauranga.

The installation in Kent was very short-lived - part of the 5km route was above a hop field, and when the hop vines were burnt at the end of the season, the wrapped cable was destroyed.

The Norwegian project was only 1km and was more of a technology demonstrator.

So, the Greerton to Welcome Bay link at approx. 8km was the then largest Rayfos installation, a record it held throughout 1983 and '84 until a 26km project in Florida in 1985.

By 2009 the "SkyWrap system" described here had more than 25,000km of retro-fitted installed cable in service.

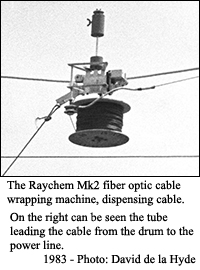

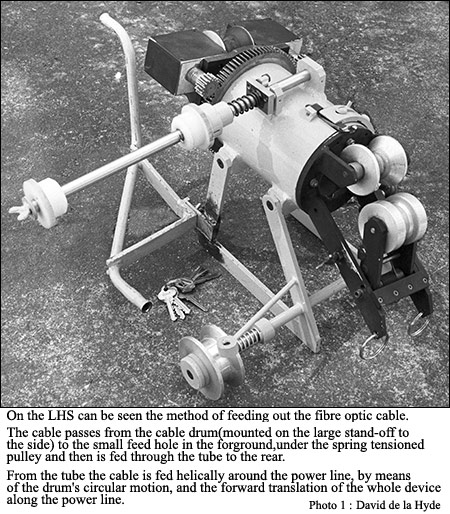

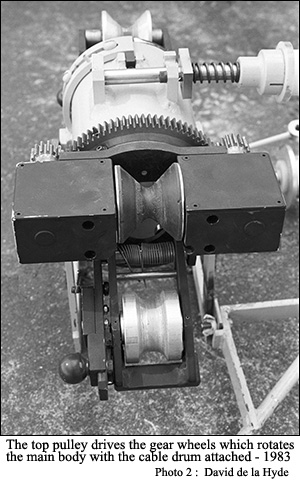

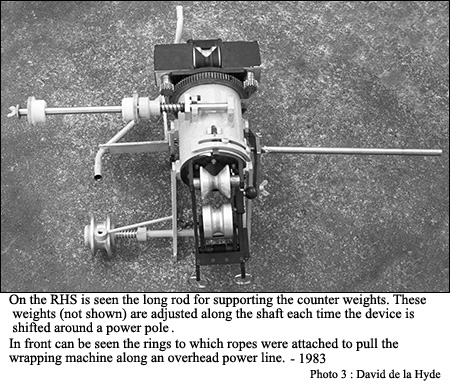

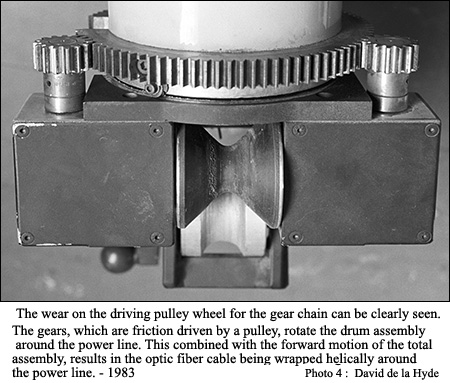

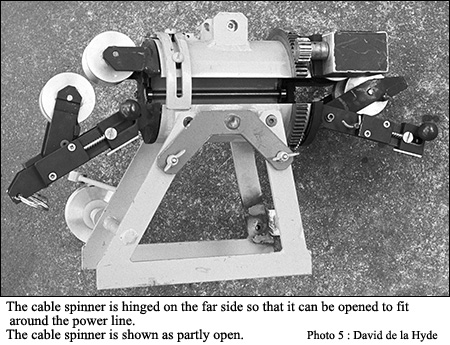

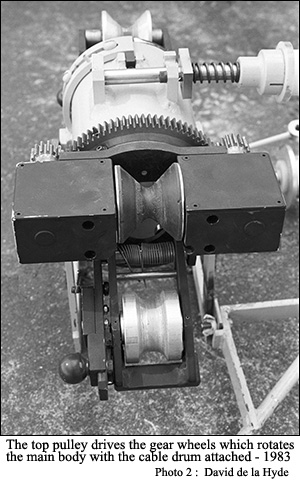

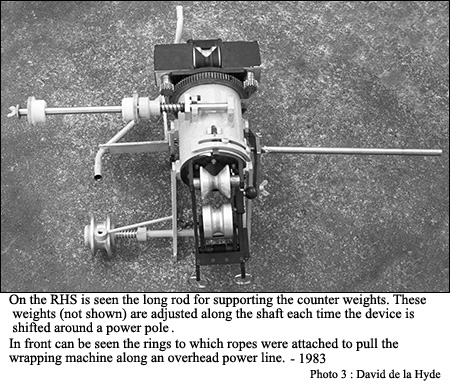

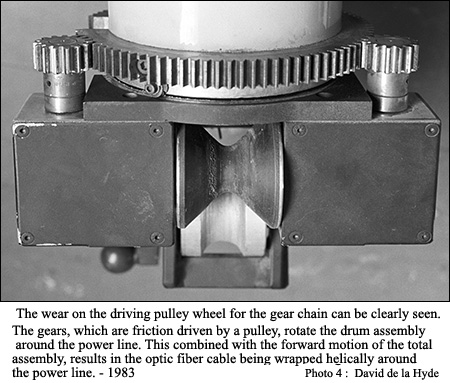

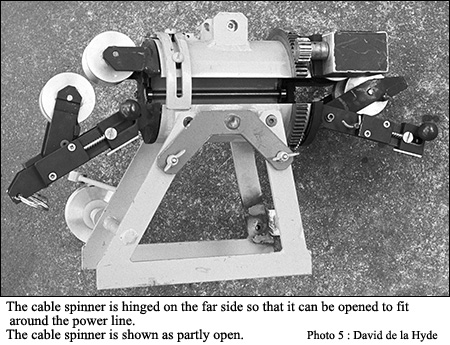

The wrapping machine in the photos is the Mk2 version and is displayed in the reception area of the AFL Swindon facility - it is no longer used for installation work!

A video showing a skywrap machine in operation can be seen on YouTube at:

https://www.youtube.com/watch?v=D0ZAwFm1my0

Note: June 14, 2016

From contacting Mr R.A. Jamieson, a former Senior Engineer with Trustpower, it appears that the installation was in service for more than 10 years.

When it failed it was found to be more expensive to repair the fault than replace it with equipment for a radio link. Therefore it was decided to establish a UHF radio link.

Trustpower replaced the copper based communications cable from the Lloyd Mandeno Station's Forebay to Lake Mangaonui with a fiber optic cable. Several kilometres of fibre was also installed in Rotorua at the Wheao Hydro Electric Scheme.

Also of interest is that the UHF communications link at the Lloyd Mandeno Forebay was replaced by a microwave link.

References:

https://www.aflglobal.com/Products/Fiber-Optic-Cable/Skywrap/SkyWrap.aspx

https://en.wikipedia.org/wiki/Optical_attached_cable

Some personal correspondence in 2009 with Jim Rowe, Product Manager, AFL Telecommunications (Formerly Raychem then FOCAS)